News

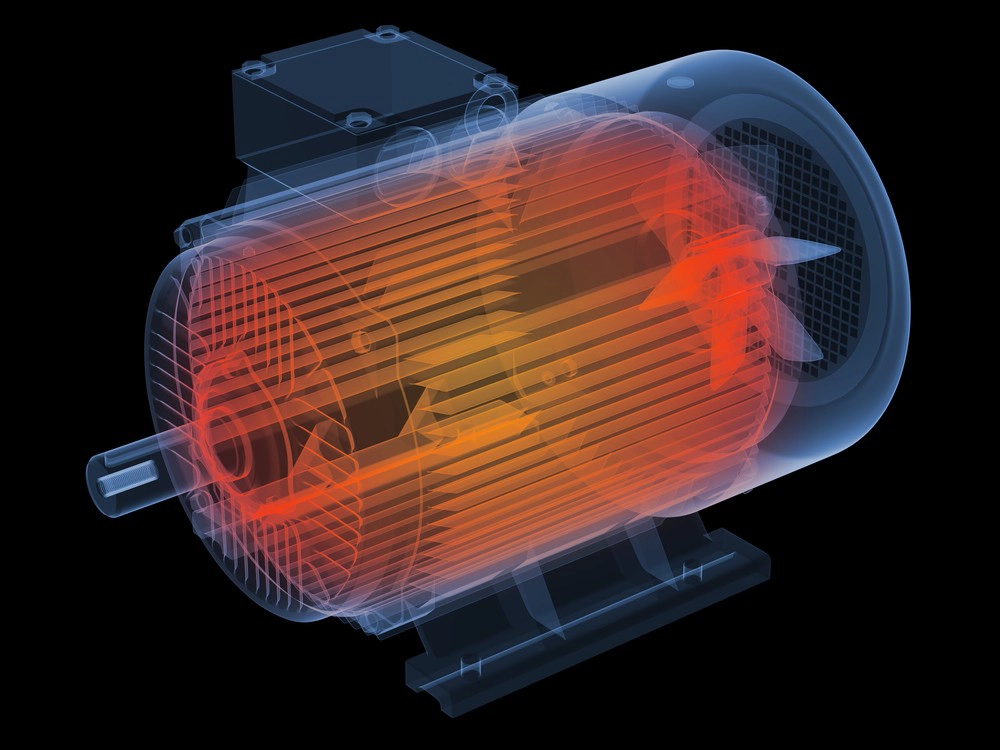

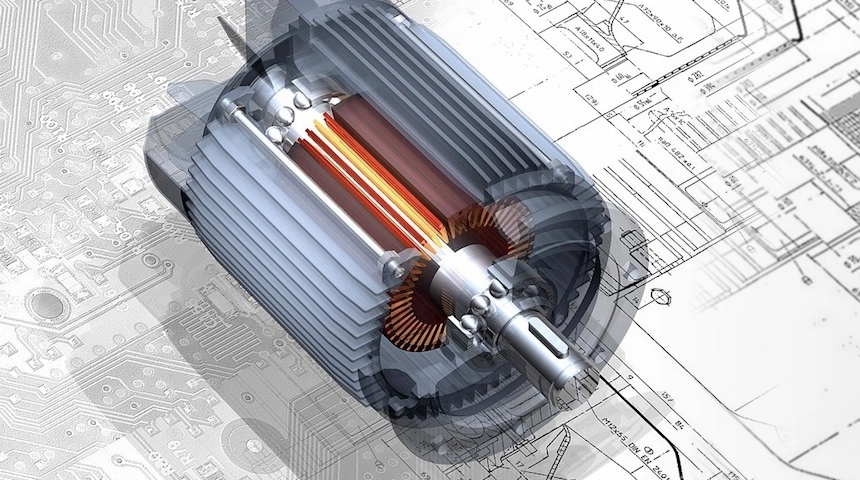

Is the motor overheating? These 8 countermeasures can help you quickly “cool down”

Have you ever encountered problems with motor overheating and frequent shutdowns? This not only affects production efficiency but may also cause irreversible damage to the equipment. The following 8 countermeasures will effectively reduce motor heating and extend the life of your equipment. Let your motor “cool down” from now on!

1. Load and mechanical inspection: avoid overload and jamming

First, make sure the motor load is within the rated range. Overload operation is one of the common causes of motor heating. You can avoid this problem by adjusting the load or optimizing the workflow. At the same time, don’t forget to check whether the mechanical part is stuck or has excessive friction. These mechanical faults will also cause the motor temperature to rise.

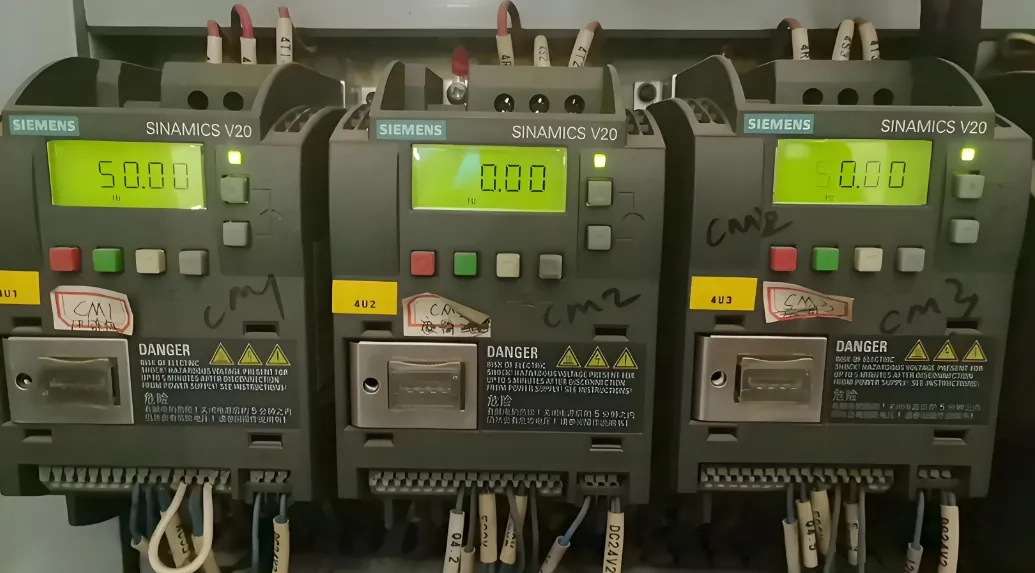

2. Adjustment of inverter parameters: Reasonable setting is the key

As the “brain” of the motor, the inverter parameter setting directly affects the motor’s operating efficiency. Ensure that the output frequency is reasonable and avoid being too low or too high. In addition, too short acceleration or deceleration time may also cause excessive current, causing the motor to heat up. Properly extending these times can make the motor run more smoothly.

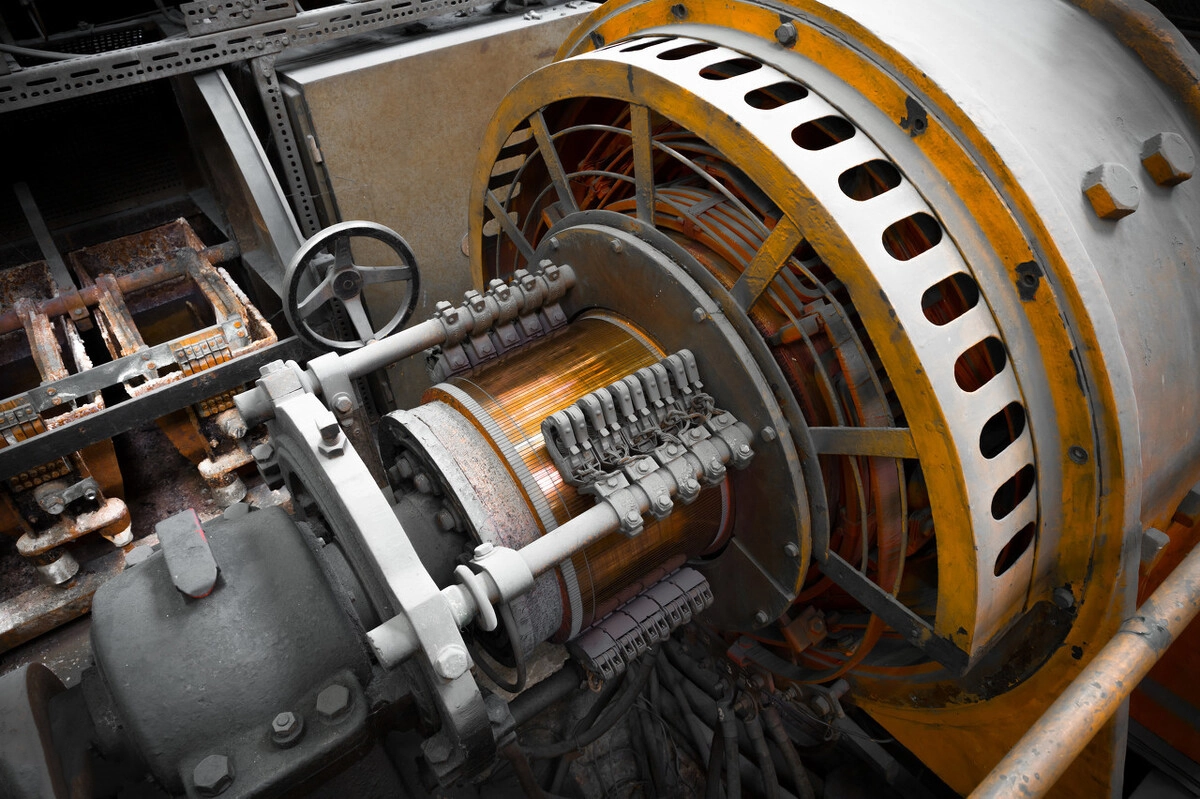

3. Motor maintenance: insulation, heat dissipation and lubrication

Aging or damage to the insulation performance of the motor will directly lead to heating problems. Check the insulation regularly and replace aging parts in time. At the same time, ensure that the fan and heat dissipation channels are working properly to avoid poor heat dissipation. Don’t forget to check the bearing lubrication and add grease if necessary to reduce friction and heat generation.

4. Power supply voltage and environmental factors

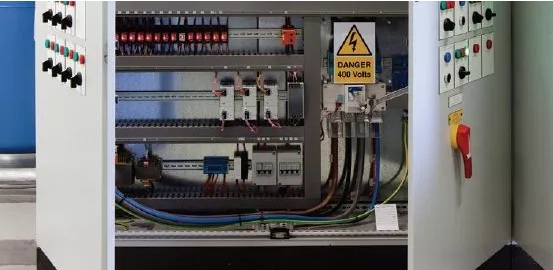

Power supply voltage fluctuation is another culprit that causes motor heating. Ensure that the power supply voltage is stable and avoid being too high or too low. In addition, harmonic interference may also affect motor performance. If necessary, installing a filter can effectively reduce harmonic interference.

5. Ventilation, heat dissipation and ambient temperature

Ensure good ventilation around the motor and avoid high temperature environments. High temperatures will increase motor heating and shorten the life of the equipment. If conditions permit, consider installing additional heat dissipation equipment or adjusting the workshop layout to improve ventilation conditions.

6. Inverter and motor matching

Make sure the inverter and motor power match to avoid the inverter being too small. An inverter with mismatched power will cause unstable motor operation, which will cause heating problems. At the same time, too long cables may cause voltage drops and harmonics. Try to shorten the cable length to reduce these effects.

7. Operating status monitoring

Install temperature sensors and current monitoring equipment to monitor motor temperature and operating current in real time. This data can help you detect potential problems in time and take measures to intervene.

8. Regular maintenance: cleaning and tightening

Clean the dust on the motor and inverter regularly to keep the equipment clean. At the same time, check whether the terminal is loose and ensure reliable connection. These simple maintenance measures can greatly reduce the problem of motor heating.

By following the above 8 countermeasures, you can effectively reduce motor heating problems and extend the life of your equipment. Regular maintenance and inspections are the key to preventing problems.