News

What are the reasons why refrigeration compressors are easily damaged?

Compressor failure problems are basically caused by the following reasons: liquid compression, fluorine-deficient operation, poor oil return, exhaust overheating, and poor system cleanliness. It can be said that these problems account for more than 90% of the total failure rate.

1. Liquid compression

(1) Phenomenon analysis:

Liquid refrigerant enters the compressor, causing liquid compression, which causes the dynamic and static disk scroll to break. When the liquid refrigerant enters the compressor cavity for compression, the incompressibility of the liquid causes the scroll to be subjected to a large lateral shear force, causing the dynamic and static disk scroll to break and the compressor to jam. In addition, the broken fragments fall onto the motor, causing the motor to short-circuit and burn.

(2) Causes of liquid compression:

The fan on the evaporator side of the system does not rotate or the pipeline is blocked. Too much refrigerant is filled during maintenance or installation, etc. Therefore, we need to adjust the appropriate amount of refrigerant to ensure that there is a heating belt at the bottom of the compressor and that it is powered on normally. For this reason, for long-term storage or low ambient temperature, the air conditioner must be preheated for 6 hours before starting, which needs to be emphasized in after-sales installation.

2. Operation without fluorine

(1) Phenomenon analysis:

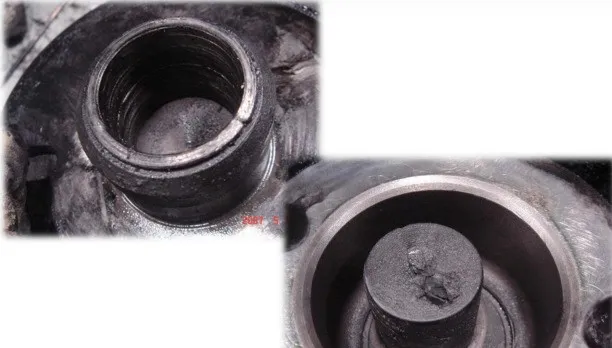

When the compressor is running without fluorine, the temperature of the center of the dynamic and static disks will rise. When it reaches a certain temperature, the end seal ring will melt, and the melt will stick between the dynamic and static disks, increasing the friction of the dynamic and static disks. In serious cases, the dynamic and static disks will be stuck or broken. At this time, the motor temperature will also rise, causing frequent IP action, resulting in failure of the protector, motor burnout, etc. In addition, due to the carbonization of the O-ring, it will cause high- and low-pressure failure, and the exhaust pressure will be low when the compressor is powered on.

(2) Causes of liquid compression:

Many cases of operation without fluorine are caused by lack of fluorine or insufficient fluorine filling in the air conditioning system. In addition, poor installation and leakage at the system head can also cause it. Therefore, after installing and repairing the equipment, check whether the pipe joints and welding points are leaking.

3. Poor oil return

(1) Phenomenon analysis:

The system has poor oil return (lack of oil). The compressor cannot deliver enough oil to the lubricating parts due to lack of oil, which makes the friction of the lubricating parts increase from bottom to top (especially the uppermost moving disc sleeve and crankshaft handle pin, because the force it bears is several times that of the other two lubricating parts below). The friction causes the moving disc sleeve to heat up, and eventually the sleeve burns out or even gets stuck. In severe cases, the sleeve will be severely worn and broken. In this case, the motor temperature rises, causing the protector to operate frequently and eventually fail. The continuous high current applied to the compressor without protection causes the motor winding to burn out.

(2) Causes of liquid compression:

① Improper startup and commissioning, long refrigeration pipeline, and insufficient lubricating oil is added during startup and commissioning.

② Improper maintenance, the air conditioning refrigeration system often leaks refrigerant, and also leaks some lubricating oil.

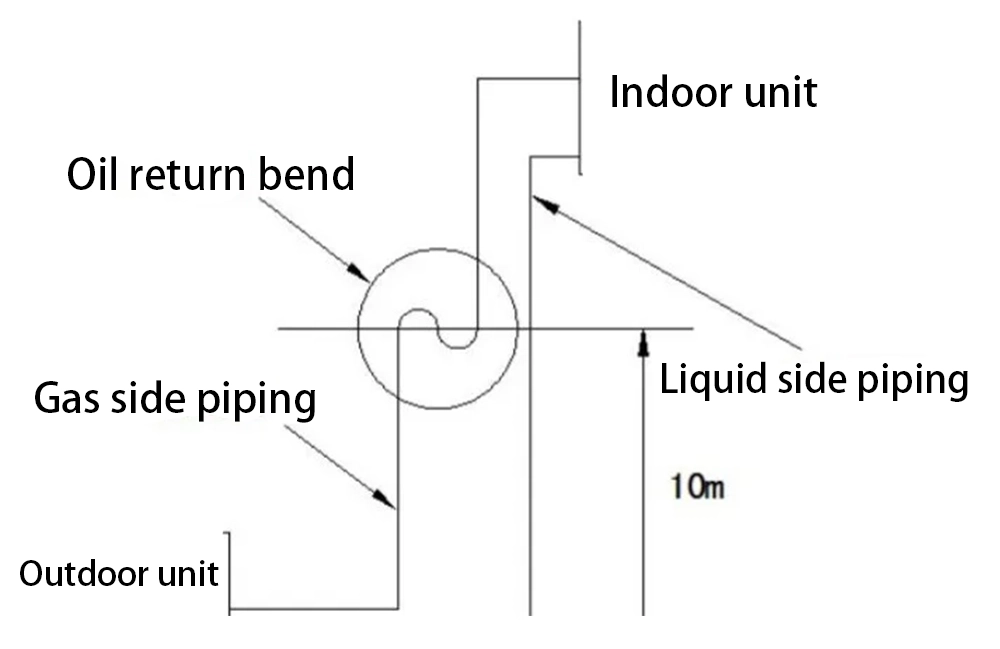

③ Improper design and installation, poor oil return. Many problems occurred in the project, such as: no oil return bend installed at the bottom; large diameter of the air pipe; long distance between oil return bends, etc.

④ Improper design and selection, the compressor starts and stops frequently, the continuous operation time is short, and a stable high-speed airflow cannot be formed in the air pipe, so the lubricating oil can only remain in the pipeline.

4. Poor system cleanliness

Poor system cleanliness may cause the refrigeration compressor to have shaft sticking, poor insulation, copper crossing and other phenomena. When welding, special attention should be paid to the entry of debris, rust and moisture into the system, because these substances are easy to produce chemical reactions when in contact with refrigerants or refrigeration oil, which will deteriorate the insulation of the motor inside the compressor. If they enter the oil supply system of the compressor, the movable parts will stick, and the shaft will stick. During installation, attention should be paid to pipeline maintenance to prevent foreign matter from entering the pipeline.

This is why it is emphasized that nitrogen must be filled when welding and piping during construction. The best state of nitrogen flow is that it can be felt by the skin (flowing nitrogen pressure 0.02Mpa). During the construction process, the end of each pipe must be sealed, and the pipeline must be purged in sections during pipeline welding. (Use 0.5MPA nitrogen for purging) Standardize vacuuming, welding and other operations.

5. Overheating of compressor exhaust

The compressor exhaust temperature is the temperature of the exhaust gas after the compressor does work (compresses the gaseous refrigerant). It is usually fixed within a range. By observing the temperature changes, the working condition of the compressor can be predicted to prevent safety hazards.

Exhaust overheating indicates that there is a problem with the operation of the refrigeration equipment. High exhaust temperature will cause serious accidents such as cylinder wear and tile burning, which will cause huge losses and will cause the cylinder to get stuck; in addition, it will cause the refrigerant and lubricating oil to deteriorate, forming harmful acidic substances in the compressor, blocking pipes, valves, capillaries or dryers and other components, seriously threatening the safety of the refrigeration system.

Common causes of compressor exhaust overheating:

① Refrigerant leakage;

② Air in the system;

③ Evaporator dirty and condenser dirty, causing refrigerant circulation to be blocked;

④ Too little or too much compressor oil will also cause the compressor exhaust temperature to be high;

⑤ Cooling fan motor burnout or poor heat dissipation will also cause the compressor exhaust temperature to be high.