News

Comparison of the advantages and disadvantages of 3 types of cylinder seals

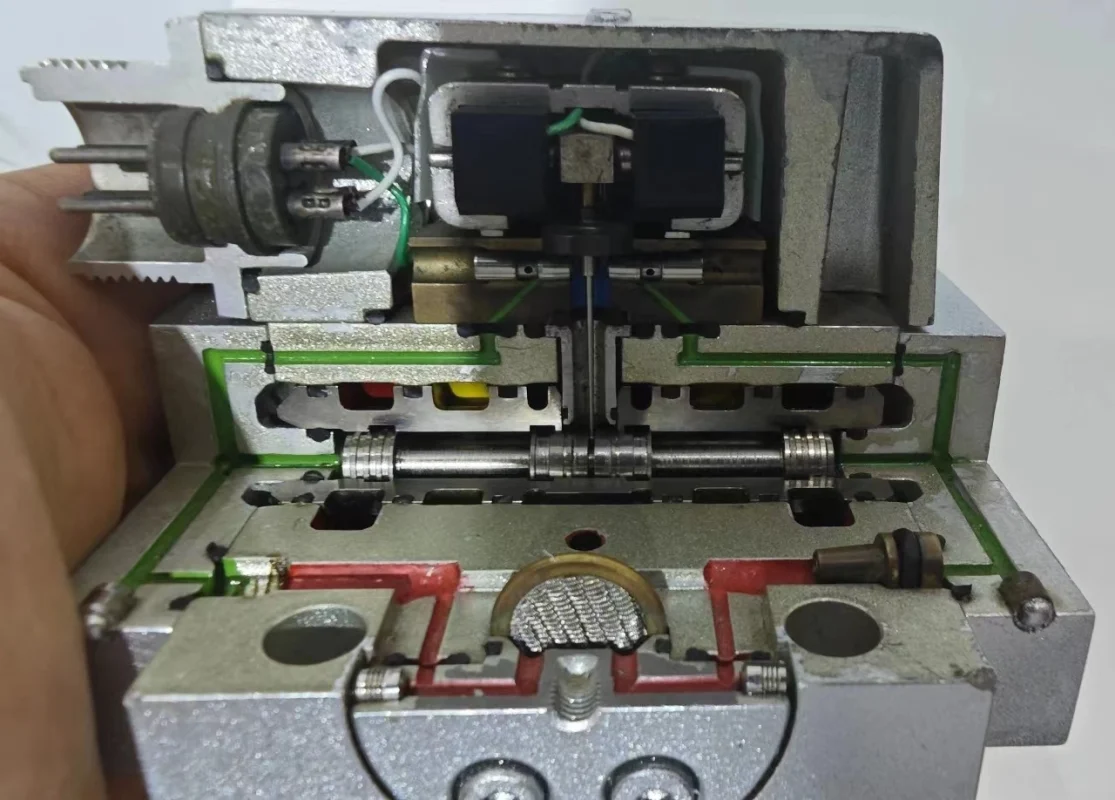

Hydraulic transmission relies on the volume change of the sealed oil chamber to transmit force and speed.

Poor sealing will cause oil leakage, which will make the mechanism movement unstable, reduce volumetric efficiency, and pollute the environment. In severe cases, the pressure cannot be built up, causing the hydraulic system to fail to work.

Therefore, the correct selection of seals is crucial to the normal operation of the hydraulic system!

There are several common sealing methods.

Gap seal: A commonly used sealing method that relies on a tiny gap between the mating surfaces of relatively moving parts to prevent leakage.

Advantages: simple, no need for heat and seals, low friction.

Disadvantages: cannot completely prevent leakage, and the sealing performance cannot increase with the increase of pressure.

Application: small diameter, low pressure, high speed, and environment with low sealing performance, such as reversing valves, hydraulic pumps (plunger pumps), hydraulic motors, etc. It is almost not used in oil cylinders.

According to the theory of axial flow in annular gaps, the leakage is proportional to the cube of the gap, so the gap can be reduced to reduce leakage. The general gap is 0.008-0.05mm, which requires the mating surface to have a high processing accuracy.

Piston ring seal: Sealing is achieved by relying on the elastic metal ring installed in the piston ring groove to fit tightly against the inner wall of the cylinder.

Advantages: The sealing effect is better than the gap seal, it can automatically compensate for the influence of wear and temperature changes, has low friction, reliable operation and long service life.

Disadvantages: The processing is complicated and cannot be completely sealed, and the processing accuracy of the inner surface of the cylinder is required to be high.

Application: The applicable pressure and temperature range is very wide, and it is generally used in high pressure, high speed and high temperature occasions.

Sealing ring seal: It is the most widely used seal in hydraulic systems. There are several types of sealing rings, such as O-shaped, V-shaped, Y-shaped and combined types. The materials are oil-resistant rubber, nylon, composite polytetrafluoroethylene, etc.

(1) O-ring

The cross-section of the O-ring is circular. When there is no liquid pressure, the elasticity of the O-ring generates pre-contact pressure on the contact surface to achieve initial sealing. When the sealing chamber is filled with pressurized oil, the O-ring is squeezed to one side of the groove under the action of the liquid pressure, and the contact pressure on the sealing surface increases, which improves the sealing effect.

When installing any shape of the sealing ring, the appropriate pre-compression amount must be guaranteed. If it is too small, it cannot be sealed. If it is too large, the friction force increases, and it is easy to be damaged. Therefore, the groove size and surface accuracy of the installed sealing ring must be strictly guaranteed according to the data given in the relevant manual.

In dynamic seals, when the pressure is greater than 10MPa, the O-ring will be squeezed into the gap and damaged. For this reason, a retaining ring made of polytetrafluoroethylene or nylon should be installed on the low-pressure side of the O-ring. The thickness of the retaining ring is 1.25 to 2.5mm. When subjected to high pressure in both directions, retaining rings should be added on both sides.

Advantages: Its structure is simple and compact, its sealing performance is good, its friction is small, its installation is convenient, and its price is low.

Disadvantages: It cannot be compensated after wear, its life is shorter than that of lip seals, the mechanical part of the sealing device requires high precision, and the starting resistance is large.

Application: It is mainly used for static sealing and sliding sealing with low speed and can be used for linear reciprocating and rotary motion, but it is more used for fixed sealing, such as sealing between pipelines, cylinder heads and cylinder sleeves. Or it can be used for low-grade, non-critical components. It can work in the temperature range of -40 to 120°C.

(2) V-ring: The cross section of the V-ring is V-shaped. The V-ring seal is composed of a pressure ring, a sealing ring (ring) and a support ring.

When the working pressure is higher than 10MPa, the number of V-rings can be increased to improve the sealing effect. During installation, the opening of the V-ring should face the side with higher pressure.

Advantages: V-ring has good sealing performance, high pressure resistance, long service life, and can achieve the best sealing effect by adjusting the clamping force.

Disadvantages: The friction resistance and structural size of the V-shaped sealing device are large.

Application: Mainly used for reciprocating motion sealing of piston rods. It is suitable for working under working pressure p>50MPa and temperature -40~80℃.

(3) Y-shaped sealing ring: The cross section of the Y-shaped sealing ring is Y-shaped (as shown in the figure below), which is a lip-shaped sealing ring. The sealing effect of the Y-shaped ring depends on the close contact between its lip and the coupling circle. Under the action of pressure oil, the lip produces a large contact pressure on the coupling surface, thereby achieving the purpose of sealing; when the liquid pressure increases, the lip and the coupling surface are closer, the contact pressure is higher, and the sealing performance is better.

When installing the Y-ring, the lip end face should face the side with high pressure. When the pressure changes greatly and the sliding speed is high, a retaining ring is added to the back side of the lip as a support ring to fix the sealing ring.

Advantages: It is a sealing ring with good sealing, stability and pressure resistance, low friction resistance and long service life, so it is widely used.

Application: Y-shaped ring is mainly used for reciprocating motion sealing. According to the different length and width ratios of the cross section, Y-shaped ring can be divided into two forms: wide section and narrow section; wide section Y-shaped ring is generally suitable for working pressure p<20MPa. Narrow section Y-shaped ring is generally suitable for working pressure p<32MPa.