News

Selection parameters and selection basis of MOOG servo valve

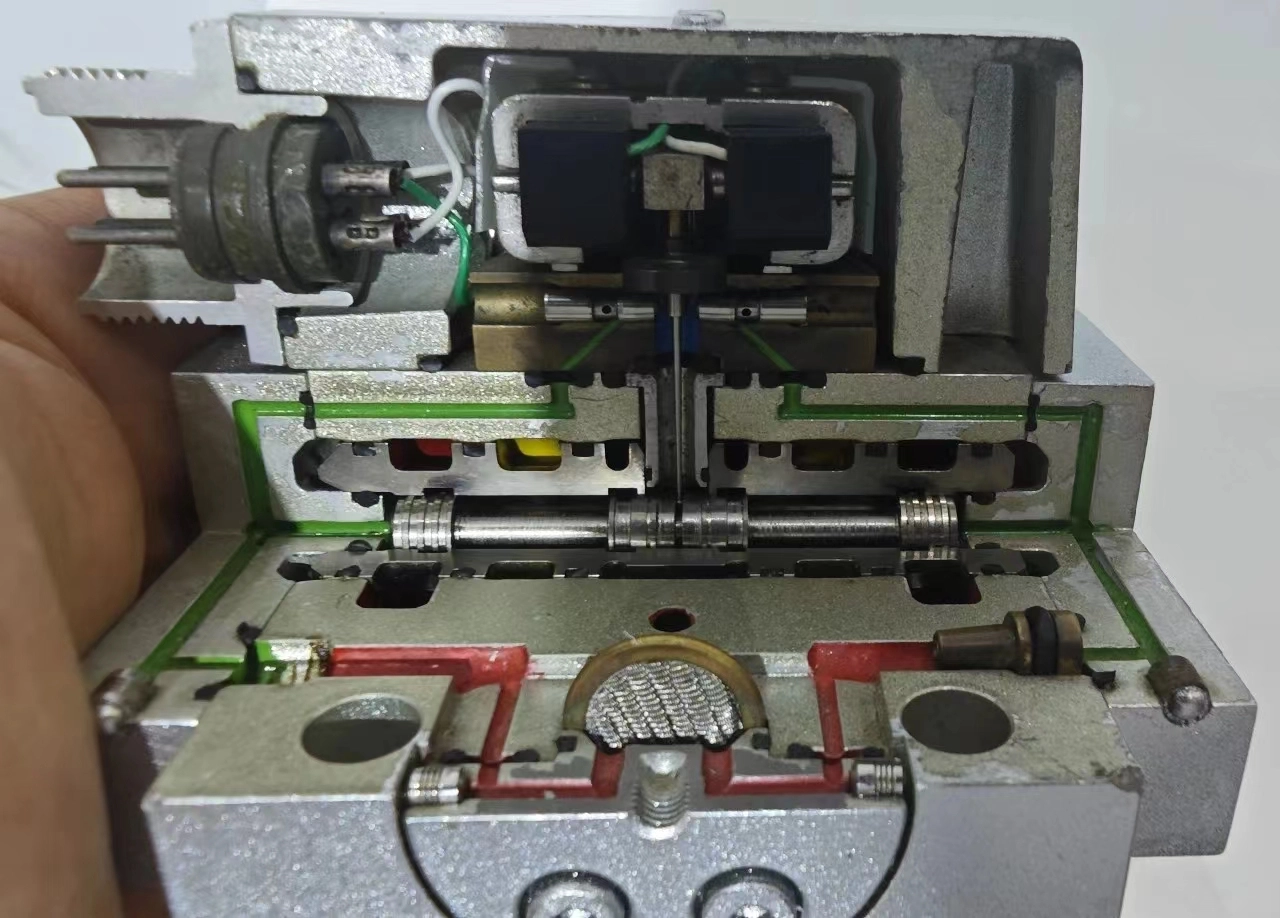

MOOG servo valve belongs to the two-stage valve, the first stage is for the nozzle plate type, by the control signal to control its outlet pressure, the second stage is for the slide valve type, the implementation of the control level to the pressure of the brake cylinder. When there is no signal, due to the pressure nozzle outlet oil pressure, so that the servo valve baffle against the return nozzle, the pressure of the oil pressure in the slide valve spool, so that the brake port and the metering of the oil port directly connected to the brake port pressure with the pilot control of the metering of the oil pressure is equal to the angular speed of the wheels to detect the skidding speed and the baseline skidding speed has a deviation, the moment motor receives the deviation of the signal, the moment motor drives the gear plate to the pressure nozzle. Motor drive gear plate to the pressure nozzle deflection, so that the role of the upper end of the spool drop in oil pressure, in the lower end of the spool under the action of oil pressure, the spool upward, shut down the metering pressure port, which will lead to a reduction in the pressure of the control port, the control port pressure is reduced to a certain value, there is a corresponding braking pressure

MOOG servo valves Product Description: MOOG servo valves mainly refer to the electro-hydraulic servo valves, which in the acceptance of electrical analog signals, the corresponding Output modulated flow and pressure. It is both electro-hydraulic conversion elements and power amplification components, it can be small power of weak electrical input signals into high-power hydraulic energy (flow and pressure) output. The electro-hydraulic servo system connects the electrical part with the hydraulic part to realize the conversion of electro-hydraulic signals and hydraulic amplification. The electro-hydraulic servo valve is the core of electro-hydraulic servo system control.MOOG servo valve is an actuator in the servo system that converts the electrical signal input into a high power pressure or flow pressure signal output. It is an electro-hydraulic conversion and power amplification element.

Servo valves have high sensitivity and good rapidity. They can convert a very small electrical signal (e.g., 10 milliamps) into a very large hydraulic power (e.g., more than tens of horsepower), which can drive many types of loads. In the past, people had nozzle stall valves, jet pipe or slide valve servo motors, and other hydraulic amplification devices included in the scope of the servo valve. since the 1970s, the servo valve generally refers only to the electro-hydraulic servo valve.

Moog servo valve principle: Moog servo valve by the permanent magnetic torque motors, nozzles, stalls, spools, valve sleeve, and the control chamber. When the input coil is energized with current, the gear plate moves to the right, so that the throttling effect of the right nozzle is strengthened, the flow rate is reduced, and the back pressure on the right side rises; at the same time, the throttling effect of the left nozzle is reduced, the flow rate is increased, and the back pressure on the left side decreases. The spool ends of the force are out of balance, the spool then moved to the left. High-pressure oil flows from S to C2, to the load. The return oil from the load flows through C1 and enters the tank. The displacement of the spool is proportional to the input current of the torque motor, and the hydraulic force acting on the spool is balanced with the spring force, so the differential current of the torque motor in the equilibrium state is proportional to the displacement of the spool. If the input current is reversed, the flow rate is also reversed. The table shows the classification of servo valves. MOOG servo valves are mainly used as actuators in electrical hydraulic servo systems (see Hydraulic Servo Systems). In the servo system, the hydraulic actuator, compared with the electrical and pneumatic actuators, has the characteristics of good rapidity, high output power per unit weight, smooth transmission, and strong anti-interference ability. On the other hand, the servo system transmits signals and corrects the characteristics of the electrical components. Therefore, modern high-performance servo systems also use electro-hydraulic methods, servo valves are the necessary components of such systems.