News

What is pressure drop? What are the effects of pressure drop in hydraulic systems?

1. Pressure drops in hydraulic system

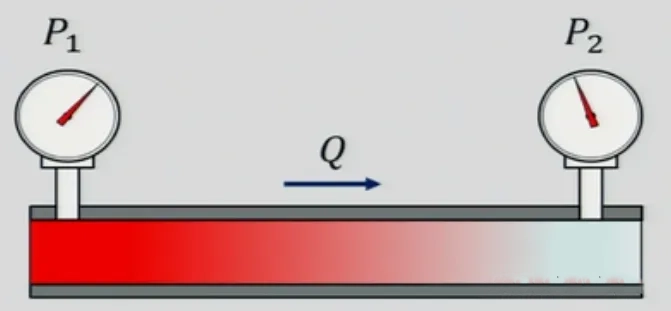

Pressure drop is a change in energy, a decrease in pressure caused by energy loss when the fluid flows in the pipe. This energy loss is caused by the collision and exchange of momentum between fluid particles when the fluid flows and overcomes turbulence. The difference in pressure between the inlet and outlet of a hydraulic system or component is called pressure drop. The flowing liquid will produce a certain pressure drop in the pipeline or control element.

The pressure drop in the hydraulic system is generally caused by the following aspects:

(1)Friction resistance: When the oil flows in the pipeline, it will produce friction with the inner wall of the pipeline, thereby generating a certain resistance.

(2)Local resistance: Complex flow states such as eddy currents will be generated in the hydraulic system, which will increase the friction resistance and resistance loss of the oil.

(3)Elbows and joints: In the hydraulic system, when the pipeline needs to be connected or turned, the resistance of the pipeline increases, resulting in a pressure drop.

2. Impact of pressure drop

The flowing liquid will produce a certain pressure drop in the pipeline or control element. There are two effects of pressure drop on the hydraulic system:

(1)Beneficial pressure drop

This pressure drop is necessary. Without this pressure drop, the hydraulic system will not work or will not work smoothly. It is often used in the following six occasions: pump control system, valve control system, pilot pressure control, speed regulation, stable mechanism movement, and synchronous mechanism movement. When using a hydraulic system with beneficial pressure drop, it should be noted that the pressure drop value should be adjusted reasonably to ensure the smooth operation of the hydraulic system. It should not be adjusted too large. Otherwise, it will cause large energy loss and serious heating of the hydraulic system.

3. Unfavorable pressure drops

Harmful pressure drops, if the pressure drop is too large, the hydraulic system will heat up seriously or damage the hydraulic parts and should be strictly controlled. Most back pressures belong to the category of harmful pressure drop.

The pressure generated by the device due to the downstream resistance or the change in the ratio of the inlet and outlet impedance of the component is called back pressure. If the harmful pressure drop is too large, the hydraulic system will heat up seriously or damage the hydraulic parts and should be strictly controlled.

Harmful pressure drop is the root cause of many hydraulic system failures, and often causes the following hydraulic system failures: self-descent of the mechanism, non-stable movement of the mechanism, chaotic movement, slow movement of the mechanism, explosion of the oil cylinder and oil pipe, damage to the solenoid valve, severe heating of the hydraulic system, etc.

4. Hydraulic system pressure drop control

The standard of hydraulic system pressure drop can vary according to different industries and specific conditions.

To effectively control the pressure, drop of the hydraulic system, we can adopt the following methods:

(1) Select the appropriate diameter of the oil pipe: According to the actual working conditions of the hydraulic system, select the appropriate oil pipe diameter to minimize the oil pipe pressure drop.

(2) Reduce the flow rate: When designing the hydraulic system, minimize the flow rate while meeting the system working requirements.

(3) Shorten the length of the pipeline: In the design of the hydraulic system, the length of the pipeline should be shortened as much as possible. Under the premise of ensuring the system working requirements, reduce the resistance loss of the pipeline and reduce the pressure drop in the system.

(4) Use low-viscosity hydraulic oil: Using low-viscosity hydraulic oil can reduce the friction resistance of the oil and reduce the pressure drop in the system.

(5) Optimize the structure of the hydraulic system: By optimizing the structure of the hydraulic system and reasonably arranging the oil pipes and hydraulic components, the resistance of the liquid flow can be reduced, and the pressure drop of the oil pipe can be reduced.